Do you see rust or damage on your metal equipment and think it’s beyond saving? Unfortunately, in some cases, that might be true. However, what if you could have prevented this entirely?

By taking proactive steps to shield your metal surfaces from corrosion, you can avoid costly repairs and replacements. For active metal surfaces like water tanks, the key lies in using the right protective measures – and cathodic protection is the answer.

What is Cathodic Protection?

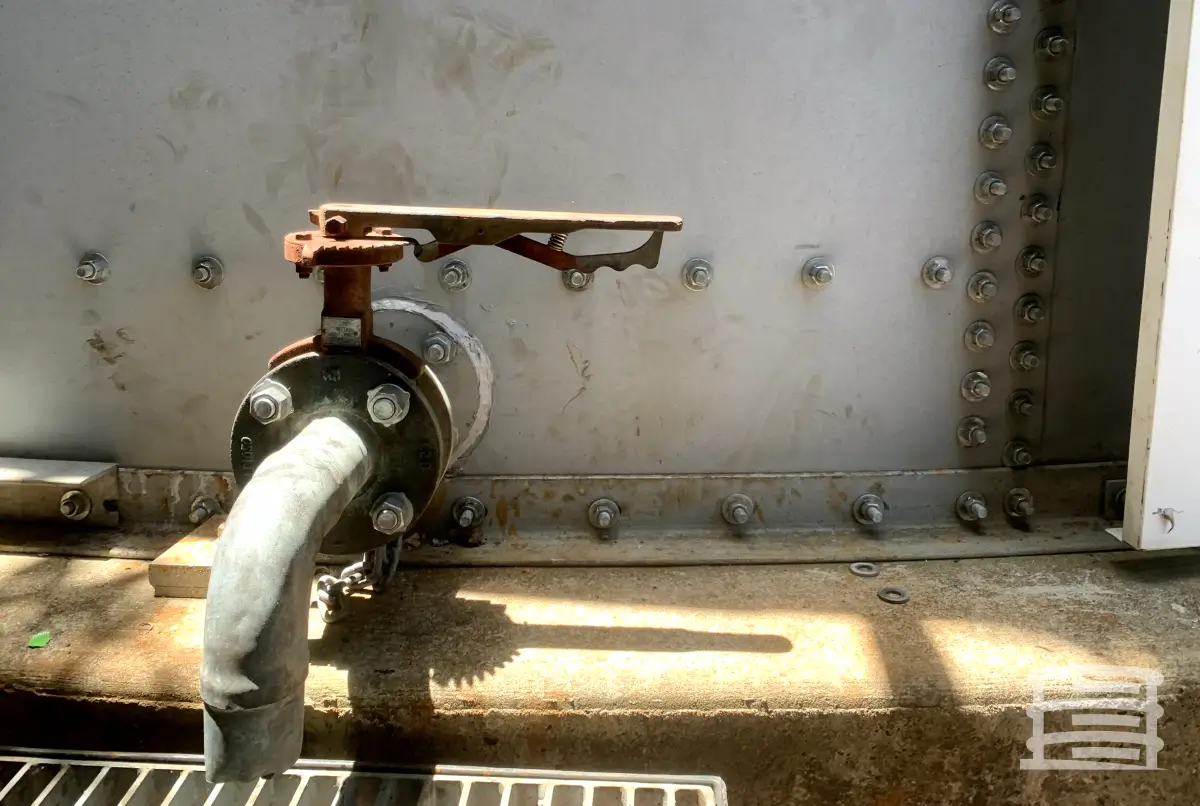

Cathodic protection is a crucial weapon in the fight to maintain water tanks. It effectively shields submerged or buried metal components within these tanks from the destructive forces of rust and corrosion. This method is a popular choice for safeguarding various elements, including the tanks themselves, piping systems, valves, pumps, and any other submerged or buried metal parts.

However, while cathodic protection is undeniably effective in preventing corrosion, it’s important to acknowledge that it can represent a significant financial investment, especially for large-scale steel assets.

Types of Cathodic Protection

The broad categories for cathodic protection services are ‘Galvanic’ and ‘Impressed Current Cathodic Protection.

Galvanic

Galvanic protection, also known as galvanization, offers a layer of defense against corrosion. It works by applying a protective coating, usually zinc, to susceptible metals like steel. This zinc layer acts like a sacrificial shield, corroding first to protect the steel underneath. However, as the zinc layer wears down over time, eventually exposing the steel, this method isn’t ideal for long-term corrosion control strategies.

Impressed Current Cathodic Protection

Impressed current cathodic protection offers a long-lasting solution against corrosion. Unlike galvanic protection, it utilizes an external power source to continuously supply electrons through anodes. These anodes, typically made from more reactive metals like magnesium, aluminum, or zinc alloys (similar to those found in batteries), act as sacrificial donors of ions. This continuous flow of electrons shields the target metal from corrosion.

Why is Cathodic Protection Important?

Cathodic protection plays a critical role in safeguarding water tanks against corrosion and preserving their structural integrity. Water tanks, particularly those used for storing potable water, are susceptible to corrosion due to continuous exposure to water and various environmental elements. Without adequate protection, corrosion can compromise the tank’s integrity, leading to leaks, contamination of stored water, and potential structural failures.

Implementing cathodic protection effectively mitigates the risk of corrosion on submerged or buried metal components, including the tank itself, piping systems, valves, and other internal parts. This protective measure significantly prolongs the lifespan of water tanks, ensures the safety and quality of stored water, and reduces the likelihood of costly repairs or replacements.

In summary, cathodic protection is indispensable for water tanks to maintain their functionality, durability, and reliability, thereby safeguarding public health and environmental safety.

Prevents Corrosion

Leakage currents from electrified railway networks, neighboring cathodic protection systems, operational welding equipment, and other direct current sources present a significant threat to the integrity of industrial water tanks and pipelines.

These currents cause electrolytic corrosion in buried metal structures, potentially leading to cracks even before the facility becomes operational. The soil, with its diverse composition and characteristics, further complicates the corrosion process, making it difficult to predict the corrosive impact on embedded metallic components, typically constructed from carbon steel.

When corrosion is identified in underground pipes and storage tanks, installing a cathodic protection system becomes essential. Such a system is crucial for mitigating various types of corrosion, including soil corrosion, galvanic corrosion, corrosion induced by leakage currents, or a combination thereof. This approach helps preserve the integrity and lifespan of the infrastructure.

Economical

Techniques like galvanizing, anodizing, and painting are widely used to prevent corrosion in various industries. These methods are particularly effective for small, above-ground pipelines that are easy to maintain.

However, for high-pressure oil and gas pipelines, additional measures are needed for robust corrosion control. Simply increasing the pipe wall thickness to meet high-pressure safety standards might not be the most economical solution. This approach could lead to lost revenue, higher maintenance costs, and production downtime.

Offers Safety and Efficiency

Cathodic protection provides a dependable solution for maintaining the integrity and efficiency of operating pipelines, particularly in corrosive soil conditions. Whenever a system is exposed to harsh environments, the consideration of cathodic protection becomes essential. It’s important to note that cathodic protection can be theoretically applied to pipelines that are buried or submerged.

In addition to coating, cathodic protection serves as an effective technique for safeguarding pipelines. In situations where the coating thickness does not meet standards or where coating quality could be improved, cathodic protection can be selectively applied to specific sections of the pipeline. Furthermore, it can enhance the corrosion resistance of bare pipelines.

To Conclude

Cathodic protection systems are a game-changer for protecting steel infrastructure, ultimately leading to better use of these valuable assets. This proven technology effectively combats corrosion on metal surfaces, making it a popular choice for safeguarding a wide range of structures. Some prime examples include pipelines, tunnels, water treatment plants, offshore oil rigs, underwater storage tanks, ship hulls, and the list goes on.

Need Tank Refurbishments? Call NFPA 25 Inspections by American Tanks Now!

At NFPA 25 Inspections by American Tanks, we understand the importance of clean water tanks. That’s why we offer a hassle-free process for keeping your tanks in top condition.

Call NFPA 25 Inspections by American Tanks at +1 800 656 0167

Or email at info@nfpa25inspections.com