Strength Meets Lightness: FRP exhibits remarkable strength coupled with surprising lightweight properties. In comparison to Steel, FRP Tanks weigh a merely 18% (5.5 times less) and an astonishing 75% less than aluminum. This results in significantly simplified installations, offering cost savings on labor expenses.

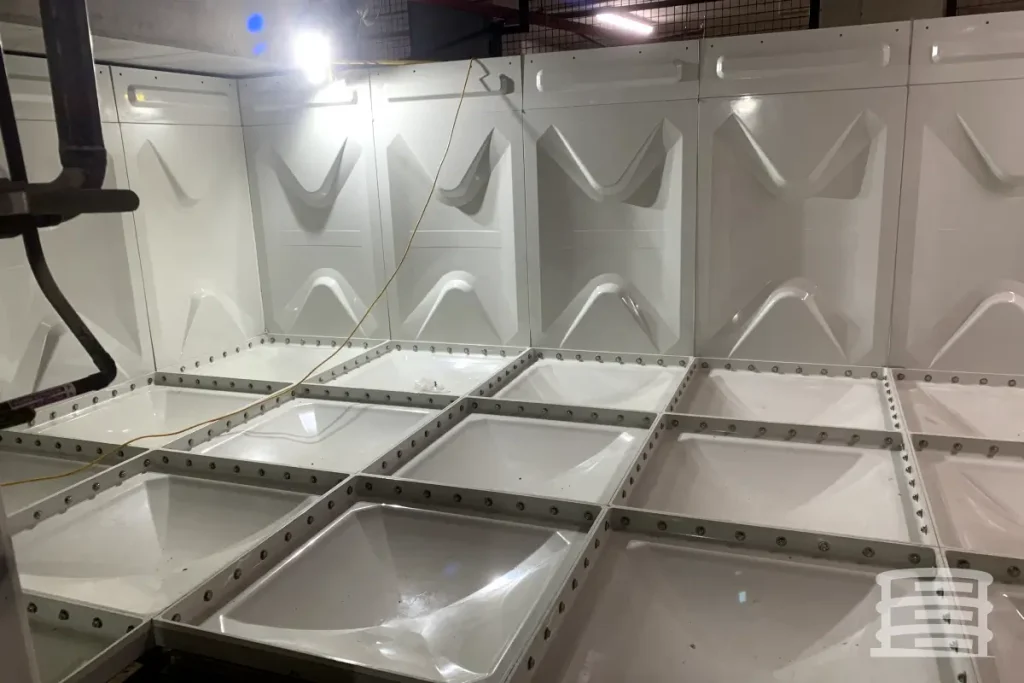

In addition to its strength and lightweight characteristics, FRP demonstrates versatility. Over the years, various materials, including concrete, polyethylene, and steel, have been utilized for industrial water tanks. However, none quite match the array of benefits provided by FRP. FRP Tanks feature a sturdy, corrosion-resistant exterior, watertight seals, and a lightweight design that facilitates easy installation. Moreover, FRP’s customizability allows for tailored solutions to suit specific needs. From underground storage to sewage tanks, FRP’s advantages extend across a wide spectrum of industrial applications. Unlike other water tanks susceptible to leakage, FRP Tanks excel in providing long-lasting, leak-free storage.

- FRP tanks offer tailored configurations and features to accommodate a variety of industrial requirements.

- FRP tanks can be constructed with capacities ranging up to 24,000 gallons.

- With cost-effectiveness and straightforward installation, FRP tanks demonstrate outstanding performance.

- FRP tanks demand minimal maintenance, ensuring prolonged functionality.

- Despite their lightweight nature, FRP tanks maintain remarkable strength.

- Forget about repainting! FRP tanks are resistant to rust and corrosion, resulting in savings of both time and money on upkeep.

- They withstand heat, stress, conductivity, severe weather conditions, and more.

- FRP boasts superior slip resistance compared to metal, making it ideal for industrial environments.

- When it comes to welding, FRP tanks exhibit the lowest flammability.

- There’s no risk of trace metal contamination in antiperspirants, shampoos, or other personal care items.

- Resin adhesives possess high strength and elasticity, effectively dampening equipment vibrations.

In the world of water storage, FRP tanks reign supreme. Unmatched in the industry for affordability, customization, and strength, they’re ideal for both industrial and commercial applications.

Advantages of Fiberglass Reinforced Plastic or Water Tank Construction:

Corrosion Resistance

One of the most significant advantages of fiberglass-reinforced plastic (FRP) tanks is their unparalleled corrosion resistance. In many environments, FRP is the optimal choice due to its ability to withstand corrosion. Even when alternatives are available, FRP’s combination of corrosion resistance and cost-effectiveness often makes it the most practical option.

The science behind this lies in the composition of FRP. The degree of corrosion resistance depends on the type and quantity of resin utilized. Generally, higher resin content results in better resistance to corrosion.

Weight Advantages

Another notable benefit of FRP is its favorable weight-to-strength ratio. Typically, FRP weighs only about one-seventh as much as steel and half as much as aluminum while maintaining comparable strength.

In applications involving pipes and tanks, the lightweight nature of FRP offers advantages in terms of both cost and installation. Lighter materials lead to reduced expenses for transportation and installation. This is particularly advantageous for installing equipment on existing structures, such as mounting scrubbers on mezzanines or rooftops. Similarly, in specialty applications like FRP tank trailers, lighter weight enhances mobility and operational efficiency.

High Strength

Strength is a crucial factor in the design of FRP equipment for demanding applications like missiles and pultruded shapes, where corrosion resistance may be less critical. The exceptional strength of FRP, combined with its lightweight properties, makes filament-wound pipes and ducts ideal choices for various applications.

Flexibility

FRP stands out for its unmatched versatility, making it ideal for unique applications. Unlike other materials, FRP offers exceptional economic adaptability. Whether you require a custom shape or equipment piece, FRP allows for the fabrication of practically any design using temporary or permanent molds. For instance, in ductwork applications, FRP enables the creation of various elbows, transitions, inlets, and flanges in different shapes and sizes, all at a minimal tooling cost. Furthermore, FRP’s versatility extends beyond new projects; it can be used to fabricate durable liners for existing structures, providing a cost-effective solution for renovation projects.

If you want the service of a truly local business, then look no further. Our friendly and experienced customer service team is here to help you! We offer tried and tested services in Houston, Texas and Longbeach, California.

Call NFPA 25 Inspections by American Tanks at +1 800 656 0167

Or email at info@nfpa25inspections.com