Potable water tanks are crucial components in various industries around the world, including oil and gas facilities. Maintaining the cleanliness and safety of this central water supply is vital for both industrial processes and personal needs like drinking, showering, and cooking. However, ensuring this can be a challenge.

The traditional approach to inspecting these tanks involves completely draining them and sending personnel in for close-up inspections. This process creates confined space hazards for workers. Additionally, tanks require cleaning or treatment after inspection, followed by refilling. This traditional method can lead to tank shutdowns lasting several days, or even longer, if extensive cleaning is necessary.

The Risks of Neglecting the Water Tank Inspections

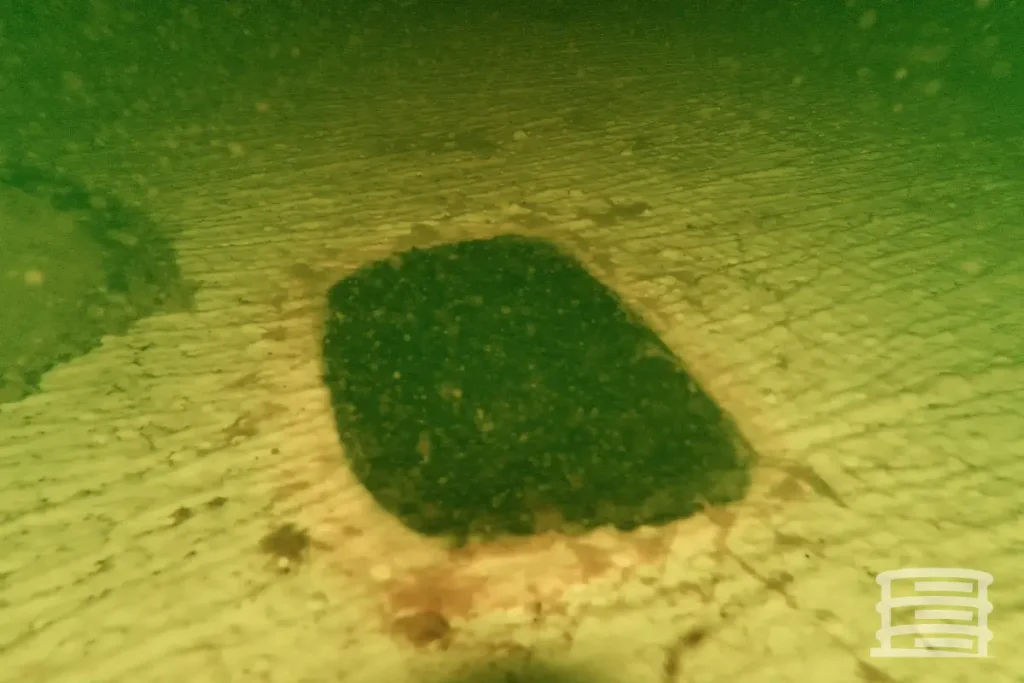

Skipping regular inspections can turn your water tank into a breeding ground for trouble. Untested tanks can harbor a variety of contaminants, from harmful microbes and chemicals to hydrocarbon residues and excessive sediment. These contaminants threaten both human health and the tank itself.

Among these dangers, Legionella bacteria deserve special attention. Legionella causes Legionnaires’ disease, a severe form of pneumonia, and Pontiac fever, a flu-like illness. Corroded tanks pose an even greater risk. Corrosion releases iron, a key nutrient for Legionella, making the environment more hospitable for these harmful bacteria to multiply. This translates to a higher risk of Legionella contamination in uninspected and corroded tanks.

ROVs: Revolutionizing Tank Inspection

ROVs have the potential to enhance traditional water tank inspection methods.

NFPA 25 Inspections by American Tanks has identified the following benefits of using ROVs:

- ROVs eliminate the risks associated with confined space entry, a requirement in traditional inspection methods.

- ROV inspections negate the need to drain and refill water tanks.

- The lengthy recommissioning process, which typically involves tank super chlorination after manned entry, can be avoided with proper ROV deployment.

- Recorded footage from ROV inspections can be retained for future reference if remedial work is necessary.

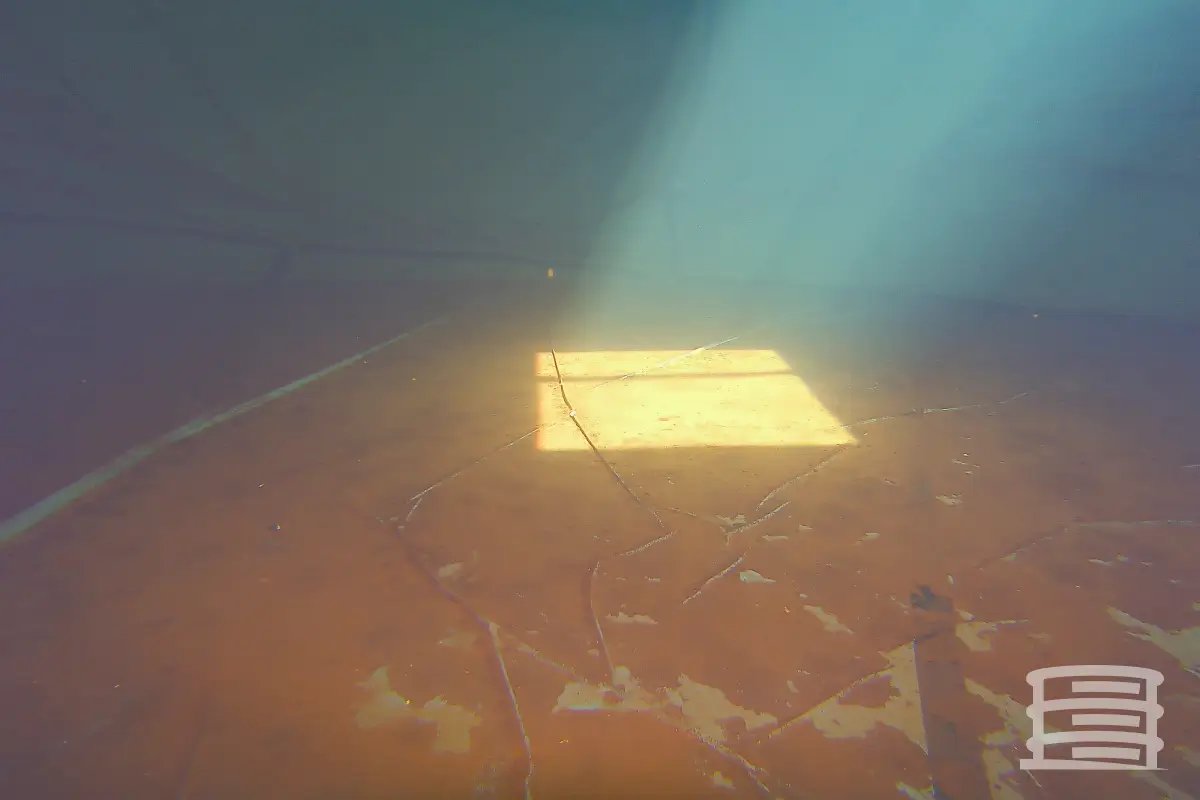

- ROV footage provides detailed, close-up views essential for examining the internal condition of a tank.

- Some ROVs feature advanced capabilities, including arms for sampling within the tank and measuring wall thickness.

While traditional methods have their place, advancements in technology offer exciting possibilities. ROV inspections provide a glimpse into the future of tank maintenance. These versatile robots can navigate tight spaces and hazardous environments that pose risks to human inspectors. Equipped with advanced technology, ROVs can conduct detailed inspections and gather data that would be otherwise unattainable.

Performing a comprehensive evaluation of a tank’s contents offers significant advantages. Accurate assessments allow for tailored cleaning proposals and more efficient cleaning jobs. Having the right information upfront translates to safer, faster, and potentially more cost-effective solutions for everyone involved.

We offer tried and tested services in Crockett, Grapeland, Kennard, Latexo, Lovelady, Ratcliff, HOUSTON, TEXAS.

We also offer tried and tested services in Longbeach, and cities, towns, suburbs, localities, and places close to Long Beach such as Lakewood, Rossmoor, Lincoln Village, Seal Beach, Hawaiian Gardens, Los Alamitos, Cypress, Bellflower, Carson, La Palma, Paramount, Cerritos, East Compton, West Carson, Compton, Norwalk, Stanton, Westminster, Lomita, Downey, Lynwood, Rolling Hills Estates, Cudahy, CALIFORNIA.

Our friendly and experienced customer service team is here to help you!

Call NFPA 25 Inspections by American Tanks at +1 800 656 0167

Or email at info@nfpa25inspections.com

1305 W 11th St #4087 Houston, TX 77008 USA

3711 Long Beach blvd Suite 4057 4th Floor # 1079 Long Beach, CA 90807 USA