Pit Liners

Pit Liners

Pit liners are used in ponds, dams, and other large underground basins to securely and efficiently contain liquids. In American industries, pits or lagoons are commonly employed for the storage of waste products or water, necessitating high-quality pit liner solutions that comply with national regulations.

In the energy sector, ponds or pits are also used for storing oil and gas, often housing substantial quantities of these materials. The primary objective of industrial pit storage is to isolate hazardous chemicals from the environment, thereby reducing human exposure and health risks.

Oil remediation is inherently dangerous, requiring drilling sites, depots, and various other facilities to be equipped with high-quality pit liners that meet operational requirements. Over our two decades of global operation, we have manufactured and replaced pit liners to accommodate the storage of numerous chemicals.

Recognizing the critical role of pit liners in containing harmful chemicals, waste products, and essential water reserves, NFPA 25 Inspections by American Tanks offers a range of heavy-duty, high-capacity solutions to meet your lining project needs.

Single Product, Multiple Uses

NFPA 25 Inspections by American Tanks manufactures pit liners designed for a wide range of water and chemical storage needs. While pit liners offer reliable containment for any storage requirement, selecting the right material for your specific application is vital to ensure optimal liner performance.

These flat liner sheets are fabricated, rolled up, and shipped for on-site installation directly into your pit.

Here are some common applications for pit and pond liners:

- Oil storage pits - Ideal for both temporary and permanent applications.

- Storage Lagoons.

- Oil Remediation Pads.

- Treatment dams - Designed to manage both wastewater and its by-products.

Key Factors for Selecting Pit Liners

NFPA 25 Inspections by American Tanks provides a variety of pit liners and outdoor lagoon liners to fit different budgets and storage requirements. However, before you choose a specific liner, it’s important to talk to our liner installation team to discuss your unique application.

PVC liners are generally a good choice for storing water and mild chemical solutions. But, to ensure you get the best liner for your needs, we’ll recommend a product based on several factors, including:

- Whether it's a temporary or a long-term solution.

- The extent of exposure to sunlight the liner will endure.

- The overall weather conditions of the area.

- The substances you plan to store within it.

- Any other potential damage the liner might be susceptible to.

For storing harsher chemicals like oils, fuels, and other byproducts, a stronger pit liner might be necessary. NFPA 25 Inspections by American Tanks understands this, and that’s why they custom-manufacture various liner materials to handle these demanding applications.

NFPA 25 Inspections by American Tanks Pit Liner Features

- Resistant to punctures and abrasions due to alloyed construction.

- Constructed with lightweight materials for easy installation.

- Engineered to withstand UV exposure for extended outdoor use, making it ideal for pits that are frequently emptied.

- Scientifically verified to withstand extreme hot and cold weather conditions.

- Corrosion-resistant.

Ideal Storage Applications

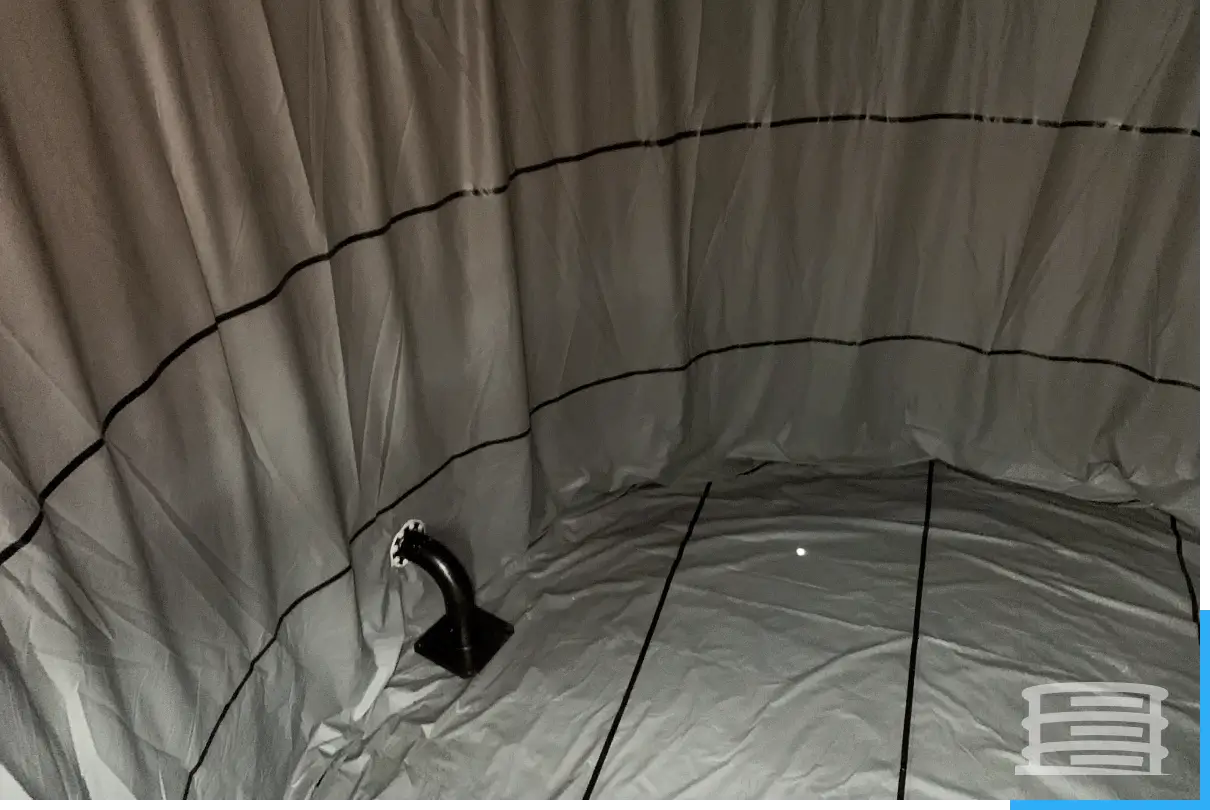

- Fittings - Bulkhead and Bung.

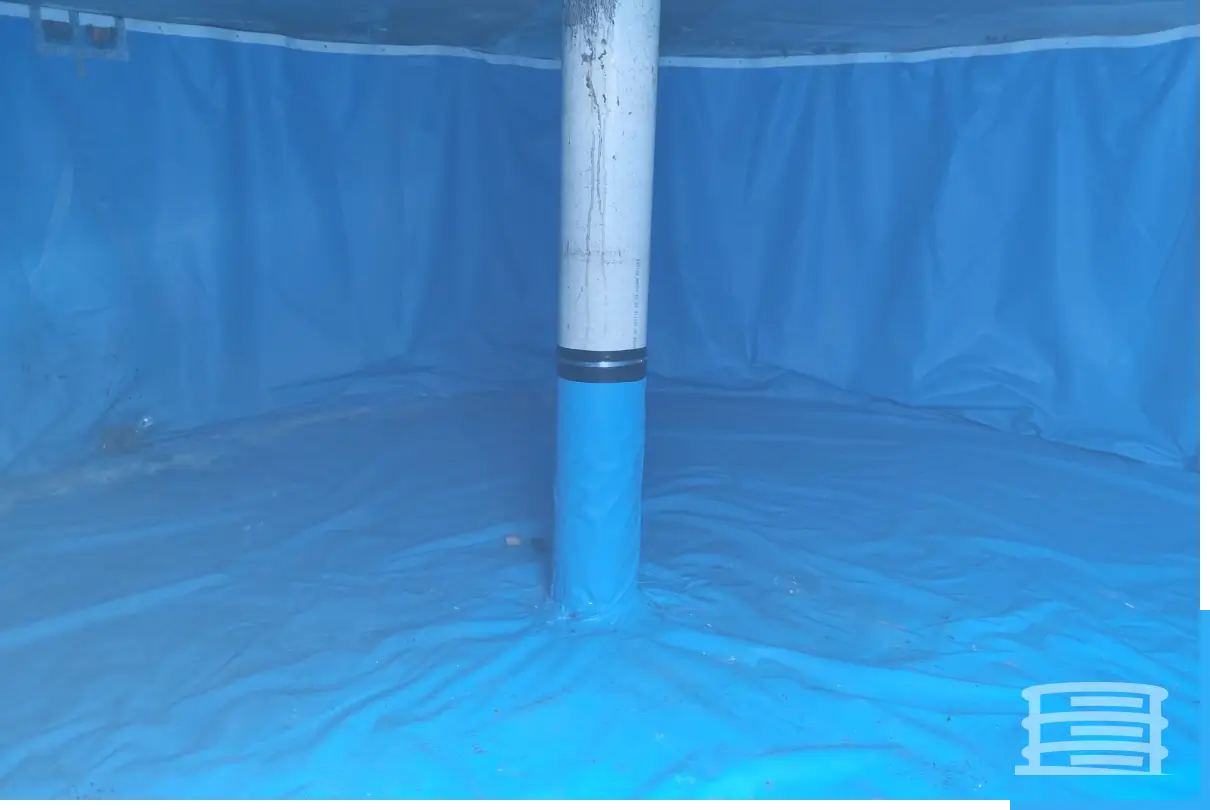

- Pipeboot.

- Liner Grips.

Easily Tailored to Specific Needs

Need a giant liner for your pond, pit, or dam? No problem! At NFPA 25 Inspections by American Tanks, we can customize, cut, and join our geotextiles to create massive, one-of-a-kind liner sheets. This eliminates the hassle of finding oversized or oddly shaped liners, as we can fuse smaller pieces together in practically any size, shape, or configuration.

Thinking about relining a massive pit larger than 10,000 square feet? NFPA 25 Inspections by American Tanks is happy to design and install a custom liner specifically for your needs!

Trouble - Free Solutions

NFPA 25 Inspections by American Tanks pit liners are built to last! They require minimal upkeep and boast outstanding tensile strength and flexibility.

Even with constant exposure to harsh sunlight or freezing temperatures, our pit and lagoon liners resist cracking, peeling, and thinning over extended use.

Since different liner thicknesses and materials offer unique benefits for various applications, we recommend consulting with our experts before you buy. This way, you can be sure to get the perfect liner for your specific needs.

Secondary Containment Pit Liners

Many outdoor chemical tanks, like those for crude oil and fuel, sit in dug-out pits. These pits act as a safety measure, catching any spills or leaks and directing them to a secondary containment system.

NFPA 25 Inspections by American Tanks is your one-stop shop for top-notch emergency containment solutions. We offer a variety of pit liner products specifically designed to handle high-volume spills.

Express Installation Services

NFPA 25 Inspections by American Tanks understands that downtime hurts your business. That’s why we can typically manufacture, deliver, and install your pit liners within just seven days of your consultation and order.

With decades of experience under our belt, our team is dedicated to getting your lagoons lined and pits operational fast – usually within a week of your purchase!

Liners for all Types of Storage Containers

- Lagoons.

- Dams and Ponds.

- Canals.

- Channels and trenches (Secondary Containment).

- Reservoirs.

- Landfill Pits.

- Concrete Pits.

- Specialized Pit Applications - Such as Water Feature Pits and Waterfall Pits.