Many commercial and industrial enterprises rely on water storage and distribution systems for their day-to-day operations. While panel tanks are essential components of these systems, traditional inspection methods for them can be problematic, consuming time and posing safety risks due to confined spaces and hazardous conditions.

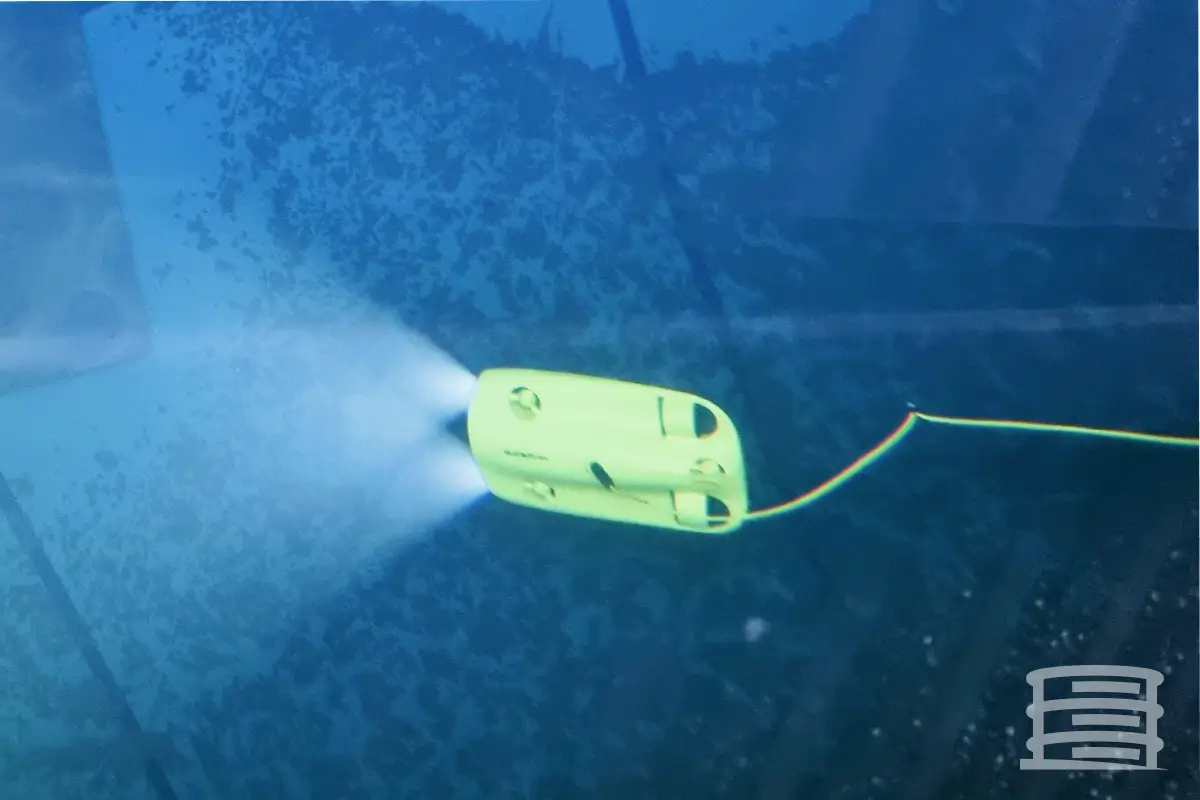

Fortunately, technological advancements have led to the streamlining of inspection processes, with underwater ROV drone technology emerging as a significant innovation. This advancement enables water companies to improve the integrity of their storage tanks and ensure the delivery of high-quality drinking water through safer, more efficient, and cost-effective inspections.

The Wider Impact of Using Drones for Panel Tank Inspections

Streamlining panel tank inspections with underwater drone technology has a significant impact on ensuring access to clean and safe drinking water, which is crucial for community well-being. Water storage tanks are essential in meeting this need, but they are prone to deterioration over time due to frequent usage and exposure to environmental factors. Issues such as corrosion, fractures, leaks, and diminished water quality can arise, eventually leading to tank malfunction.

To address these challenges, regulatory bodies like the AWWA and NFPA advocate for regular inspections of water storage tanks to maintain their optimal condition. However, traditional inspection methods, which typically involve visually examining tank components, can be labor-intensive, expensive, and potentially hazardous for inspectors, especially if they need to enter the tanks themselves.

The latest advancement in underwater drone technology provides a solution to these challenges by enabling more efficient inspections of FRP panel tanks. With underwater drones, inspectors can remotely access tanks and capture high-resolution images of tank components without the need for physical entry. This technology streamlines the inspection process, allowing inspectors to swiftly and effectively identify and address faults, thereby preventing more severe issues.

List of AWWA and NFPA Recommendations for Streamlining Panel Tank Inspections

AWWA and NFPA have established guidelines and recommendations for inspecting water storage tanks, outlining criteria and best practices for maintaining and inspecting these tanks to ensure their safe and efficient operation.

Here are some key recommendations provided by AWWA standards and NFPA to streamline panel tank inspections:

- Utilization of technology: Both AWWA and NFPA advocate for the use of technology, such as underwater drones, to capture high-resolution images of tank components without the need for human entry. This approach has the potential to significantly reduce the time and costs associated with current inspection methods.

- Safety measures: Both AWWA and NFPA 25 guidelines for fire protection systems recommend implementing safety measures during tank inspections. These measures include ensuring proper ventilation, ensuring all safety equipment is functional, and restricting inspection activities to qualified personnel.

- Repairs and maintenance: Both AWWA and NFPA stress the importance of promptly addressing any issues identified during inspections to prevent further deterioration or damage. Regular maintenance tasks such as cleaning and painting should be conducted to maintain the tanks’ condition.

Advantages of Adhering to AWWA and NFPA Recommendations for Panel Tank Inspections

Adhering to AWWA and NFPA standards for streamlining panel tank inspections is crucial for ensuring the safety and efficiency of water storage tanks. By leveraging technology, implementing safety protocols, documenting inspections, and carrying out necessary repairs and maintenance, water utilities can mitigate potential risks to public health and safety and prolong the lifespan of their tanks.

Here are some of the advantages of adhering to AWWA and NFPA requirements for panel tank inspections:

- Enhanced safety: Regular inspections help identify potential hazards, ensuring that the panel tank remains safe for use and minimizing the risk of accidents.

- Extended longevity: Following recommended inspection and maintenance protocols can extend the panel tank’s lifespan, potentially reducing costs associated with premature replacement.

- Regulatory compliance: Conforming to AWWA testing standards and NFPA regulations ensures that the panel tank meets industry benchmarks and regulatory requirements, reducing the risk of penalties and legal issues.

- Maintains water quality: Properly maintained panel tanks help ensure the quality of stored water, which is critical for public health and safety.

- Enhanced effectiveness: Regular inspections enable the identification of areas for improvement, such as reducing leaks or optimizing water flow, enhancing the efficiency of FRP panel water tanks.

Need a Panel Tank Inspection? We Meet AWWA & NFPA Standards

With AWWA and NFPA advocating for regular water tank inspections, it’s crucial for water tank service providers to stay updated on the latest technology to offer excellent service to their clients.

At NFPA 25 Inspections by American Tanks, our team of experts is ready to meet all your water tank service needs. Remember, prioritizing regular inspections and maintenance is vital for ensuring the safety and reliability of your water storage system. Let’s work together to uphold the safety and well-being of our communities.

Call NFPA 25 Inspections by American Tanks at +1 800 656 0167

Or email at info@nfpa25inspections.com